Gantry Servo V Groover Machine

- Gantry type, convenient for loading and unloading.

- Air cooling without environmental pollution, 3 +1 axis numerical control, servo control, realize automatic operation processing, improve groove machining accuracy.

- The imported hydraulic control system is used as power, with high pressure, reliable fastening, low noise and low energy consumption.

- Precision grinding gear, 45 steel forging quenching and tempering helical rack guide rail drive, the moving speed can be adjusted by frequency conversion, and the cutting process is stable.

- The NC program design is reasonable, easy to control, and can be completed only by inputting the processing size.

- According to different materials, the processing speed can be adjusted by knob, which is convenient for operators.

High lights

V Groover machine use EasyCat touch screen controller

Korean Chloe Alloy Knife

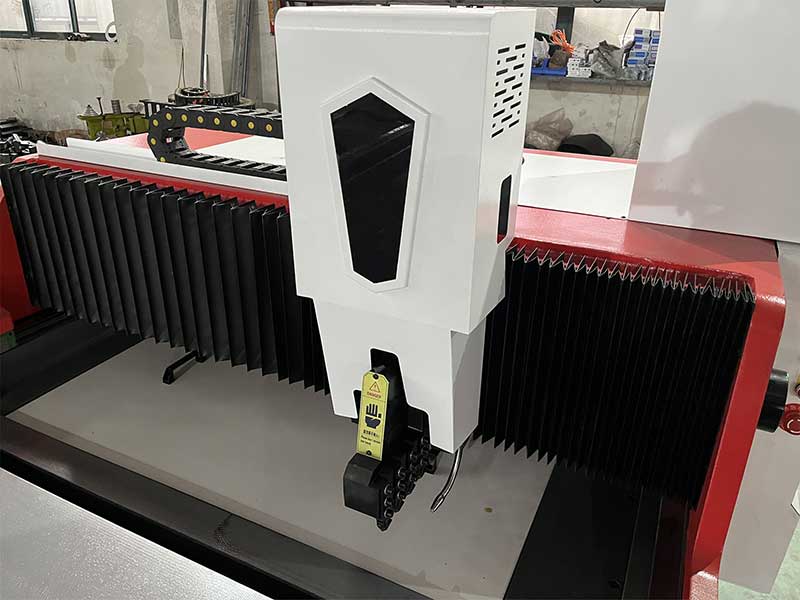

Gantry structure

Gantry structure

High efficient working bed

One-piece processing bed

Taiwan HIWIN Linear Guider

Taiwan HIWIN Linear Guider

X Y1 Y2 Z Axis use servo motor

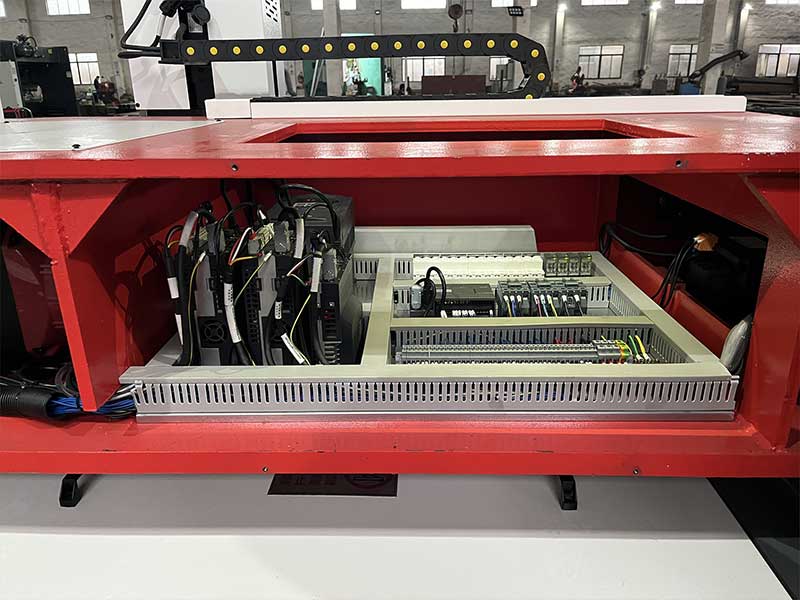

Electrical components Schneider

Learn more about our complete product range

About ZWHOPES V Grooving Machine

ZWHOPES V Grooving Machine have been manufactured since 1991 and have been installed and working in a wide variety of sheet metal cutting operations for many industries. Years of experience has helped us develop durable, low distortion and precise Groove machines.

V grooving machine is extremely useful in precision works and bending of corners to maintain the edges. Bending of metals and alloys utilizing V groove machines allow for it to be folded to a tight radius or sharp corners. Depending on the thickness of the material and the type of fold required, the V grooving cutting machine cutting head will run a programmed number of times along the sheet material.

At ZWHOPES, we employ precision V grooving machines which aid in the improvement of precision. Our sheet metal grooving machine provides sharp bends, radii, and corners, while additionally reducing material, transportation, and installation costs.