Open-type Double-drive Fiber Laser Cutting Machine

- Mechanical structure adopts gantry type, stable performance and stable equipment operation.

- Professional CNC control system, with laser power adjustment function, to guarantee cutting quality and easy operation.

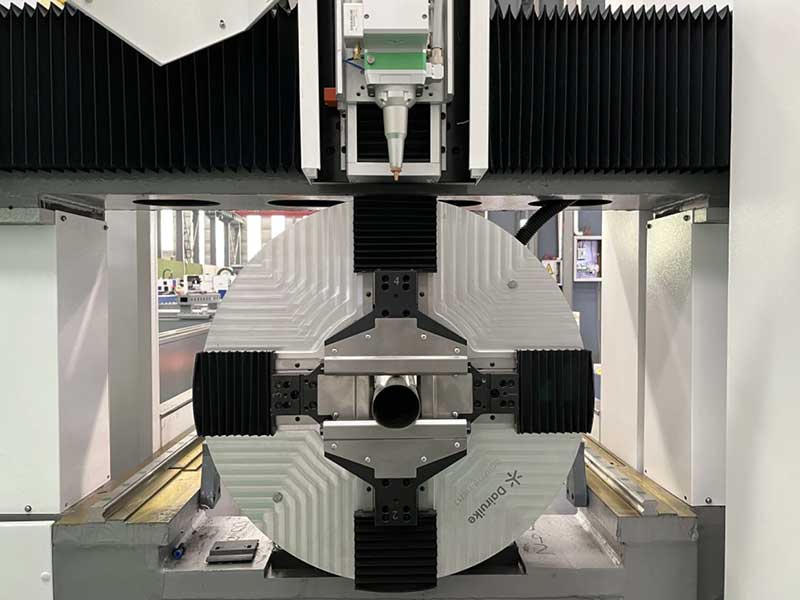

- This machine adopts AC servo motor drive system, and the machine’s motion mechanism adopts gear and rack dual drive transmission to ensure the high speed, high precision and high reliability of the equipment.

- The air circuit system adopts integrated control, advanced design, a full set of imported pneumatic components, and can access different auxiliary gases at the same time. Customers can freely choose the gas according to the actual situation.

- High quality, high efficiency fiber laser generator, low processing cost, energy saving and environmental protection.

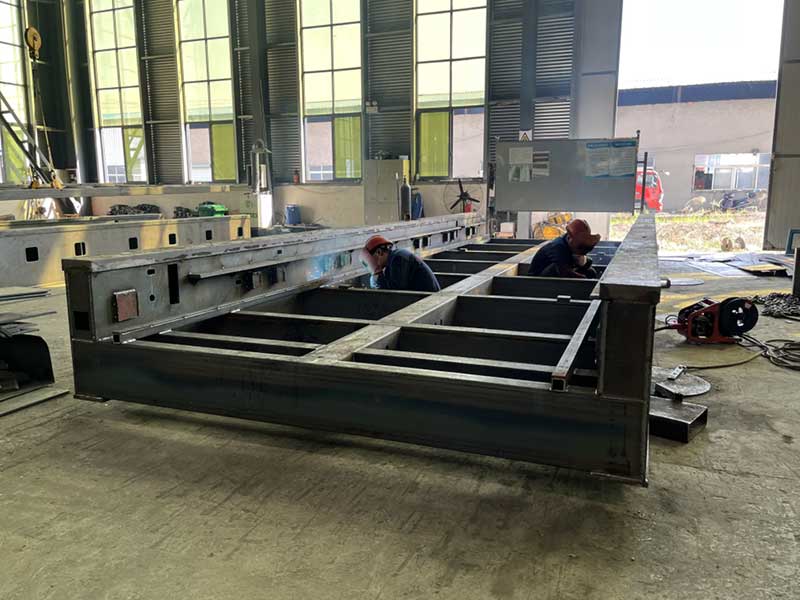

Scientific and stable machine body

Chimeric welding method

The anti-deformation method, margin method and rigid blessing method are adopted to prevent welding deformation. The chimeric welding method is adopted to ensure the stability of the bed.

The bed is processed as a whole

The mobile gantry milling machine is used to carry out integrated processing of the bed to maintain stability and shock resistance. Improve accuracy.

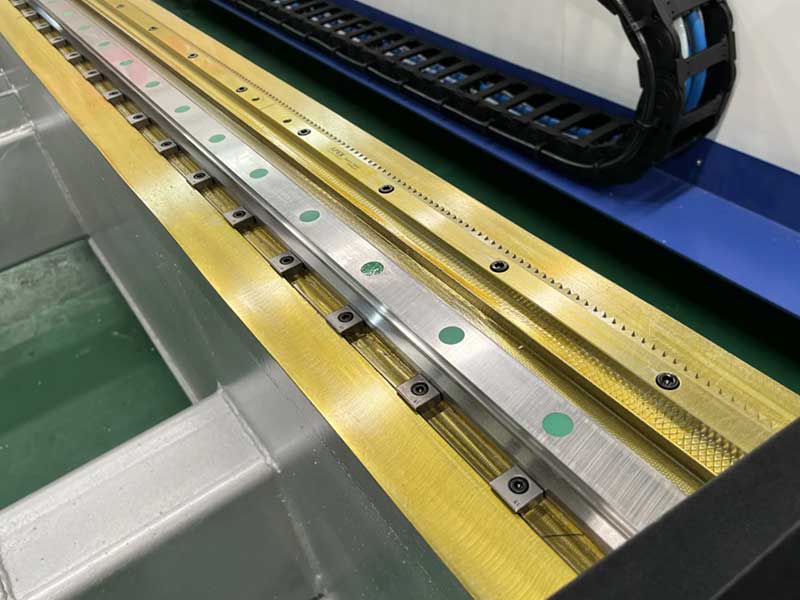

The overall machining accuracy of the beam is guaranteed

- The straightness of the beam base.

- The perpendicularity of the three faces.

- The accuracy of the guide rail and rack/ slide base verticality.

- The center moment of the guide rail and rack

- Mounting hole center distance

Innovative oil circuit system

There are 4 oil guide pipes in the fuselage and 2 oil pipes in the beam. Improve oil spills, reduce rack rail wear by increasing the number of oil strokes, ensure accuracy, and prolong service life.

Ultra-wide table plate, 7mm whole piece of steel plate

25cm ultra-wide table plate, 7cm whole steel plate, to ensure the high efficiency and stability of the gear rack.

Bed structure

- 10mm integral steel plate welded bed

- Briquetting table surface 60 mm overall welding

- 12mm stiffener

- Rectangular tube perforated welding

Need help finding a machine?

We will gladly assist you in making the right decision to achieve your business goals.

If you would like to have a question then get in touch today, we are ready to assist 24/7.

We welcome your cooperation and we will develop with you.

Main machine parts

CYPCUT System

China famous brand

RAYTOOLS cutting head

Which provides best cutting quality, best performance in the industry

Japan Panasonic servo motor/driver

Raycus lasers divergence specifications

Raycus lasers divergence specifications are far superior than other lasers and allow the use of long focal lenght processing lenses for vastly improved depth of field, less damage to optical components.

Maximum compact precision (±)

Accuracy of HANLI chiller for laser cooling +/‐ 1.0°C and for optic cooling +/‐ 0.5°C. Water temperature stability for stable laser and best cutting quality. Laser source ( Slabs), the cutting head are cooled by chiller.

Our Work Shop

Technical Specifications

| Models | Efficient working size(mm) | Optional laser power(watt) |

|---|---|---|

| ECO-fiber 3015 | 3000*1500 | 1000 |

| ECO-fiber 4015 | 4000*1500 | 1500 |

| ECO-fiber 4020 | 4000*2000 | 2000 |

| ECO-fiber 6015 | 6000*1500 | 3000 |

| ECO-fiber 6020 | 6000*2000 | 4000 |

| ECO-fiber 6025 | 6000*2500 | 6000 |

| ECO-fiber 8025 | 8000*2500 | 8000 |